August 16 2021 Two FYG shipborne HZS120D concrete mixing plants left FYG’s manufacture base in Haiyang and are being delivered to customers in Malaysia. They will produce concrete for the Malaysian cross-sea bridge, one of the most important infrastructure projects for Malaysia and surrounding countries.

The two HZS120D concrete mixing plants are smartly arranged on one hull according to customer’s hull structure, and there are sand-stone yard, working area and living area on the hull. Due to the small size of the hull, a reasonable layout is essential. Firstly, it is considered to reduce the overall height of the mixing plant, which is convenient for the operation of the hull and reduces the influence of bad weather on the hull. In order to make full use of the hull space, the sand and stone batching machine is rearranged, which not only saves space, but also achieves the goal of convenient and efficient storage, batching and transportation, get the full approval of the customer.

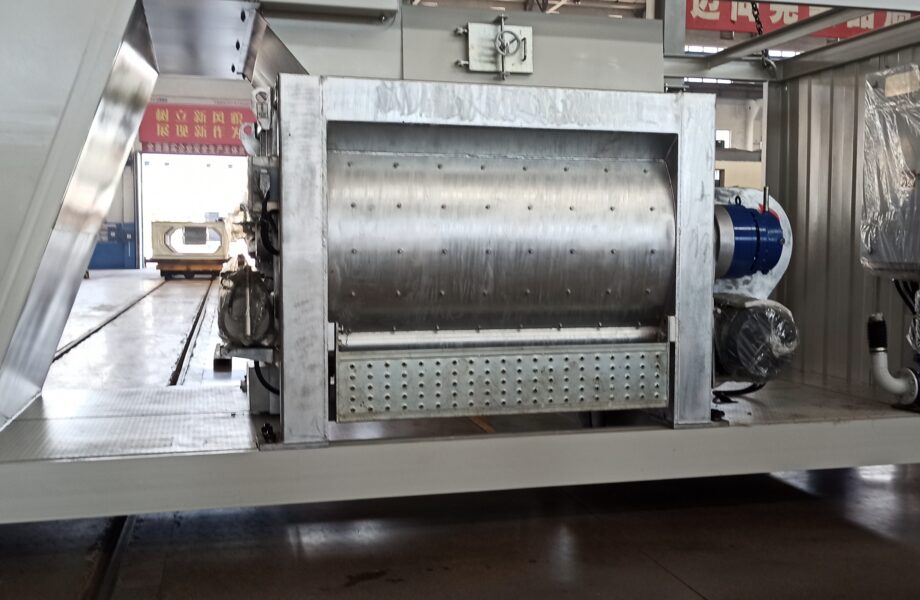

FYG’s modular concrete mixing plants are designed for minimum space requirement and large quantities of concrete production performance, durable container modules enable economical transportation, minimum time and operations of erection and disassembling, robust structure reduces the requirement of foundation, leading to economical plant relocations, plant fully enclosed and protected from harsh environment, also low noise and dust emission.